High Quality Strainers For Your World Class Equipment

Get A Free Advice

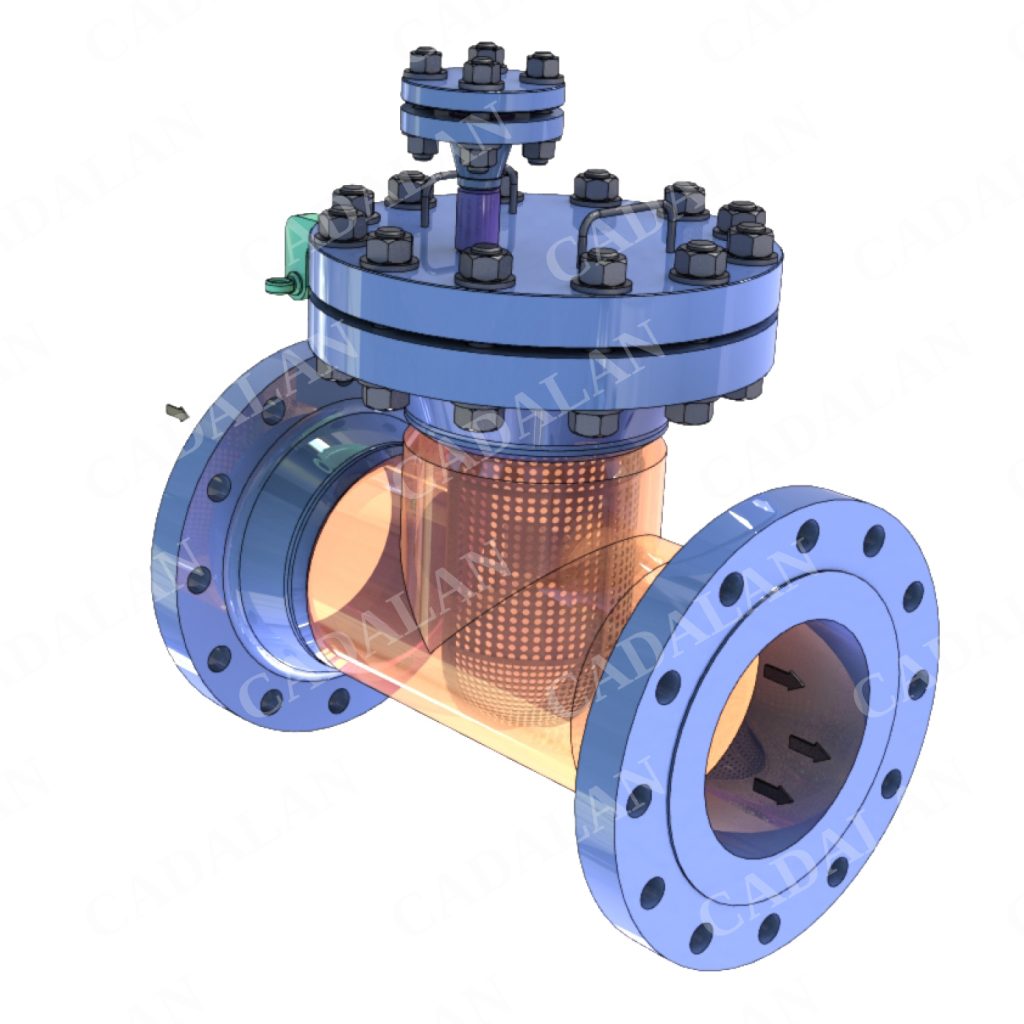

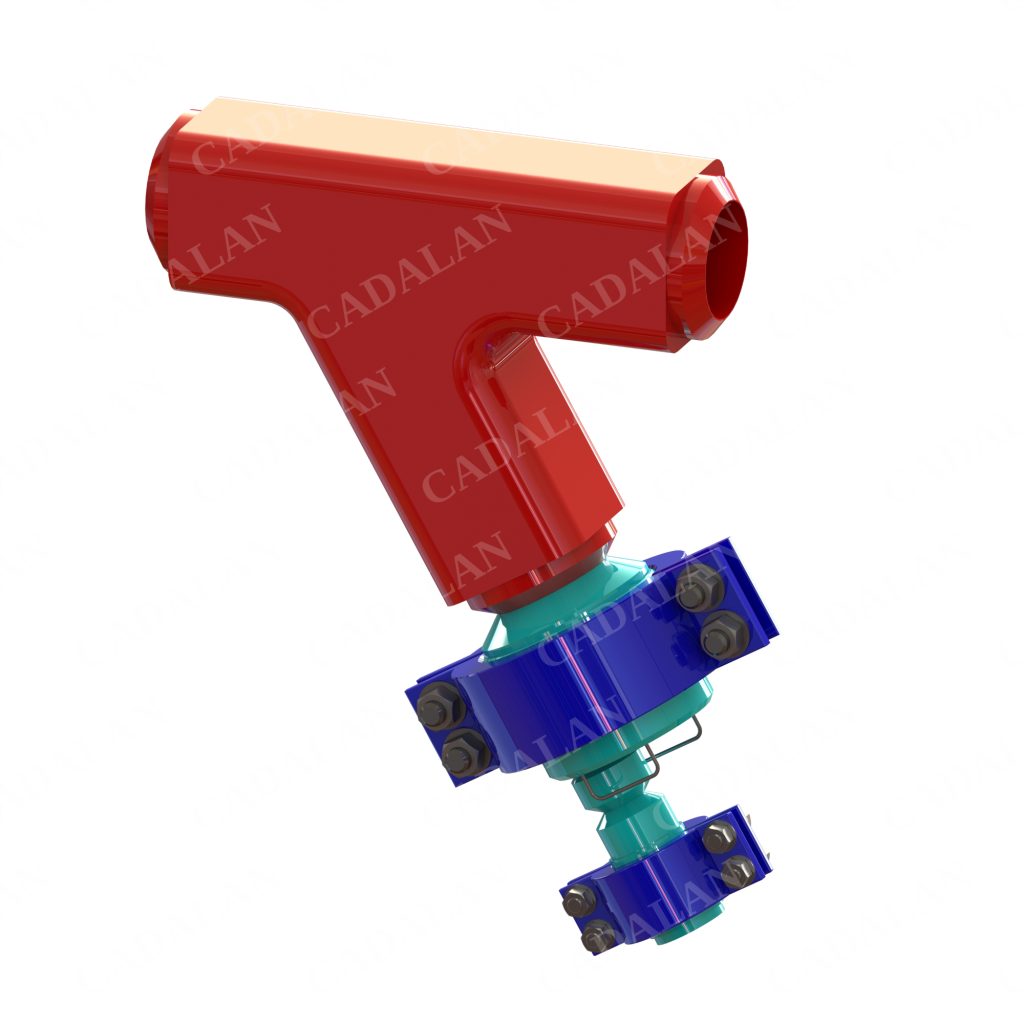

T Strainer

The strainer is very compact, important in applications where space is restricted. Unlike most other strainers, Tee Strainer can be used in both vertical and horizontal installations. A real time saving feature of Tee Strainer is that the strainer screen can be cleaned without draining the strainer vessel.

- Size: 1″ – 48″ inches

- Types: Casting, Fabricated & Butt Welded

- Connection: Flanged & Butt Welded

- Class: #150, #300 , #400 , #600, #900, #1500, #2500 up to #10,000 depending upon the customer requirements

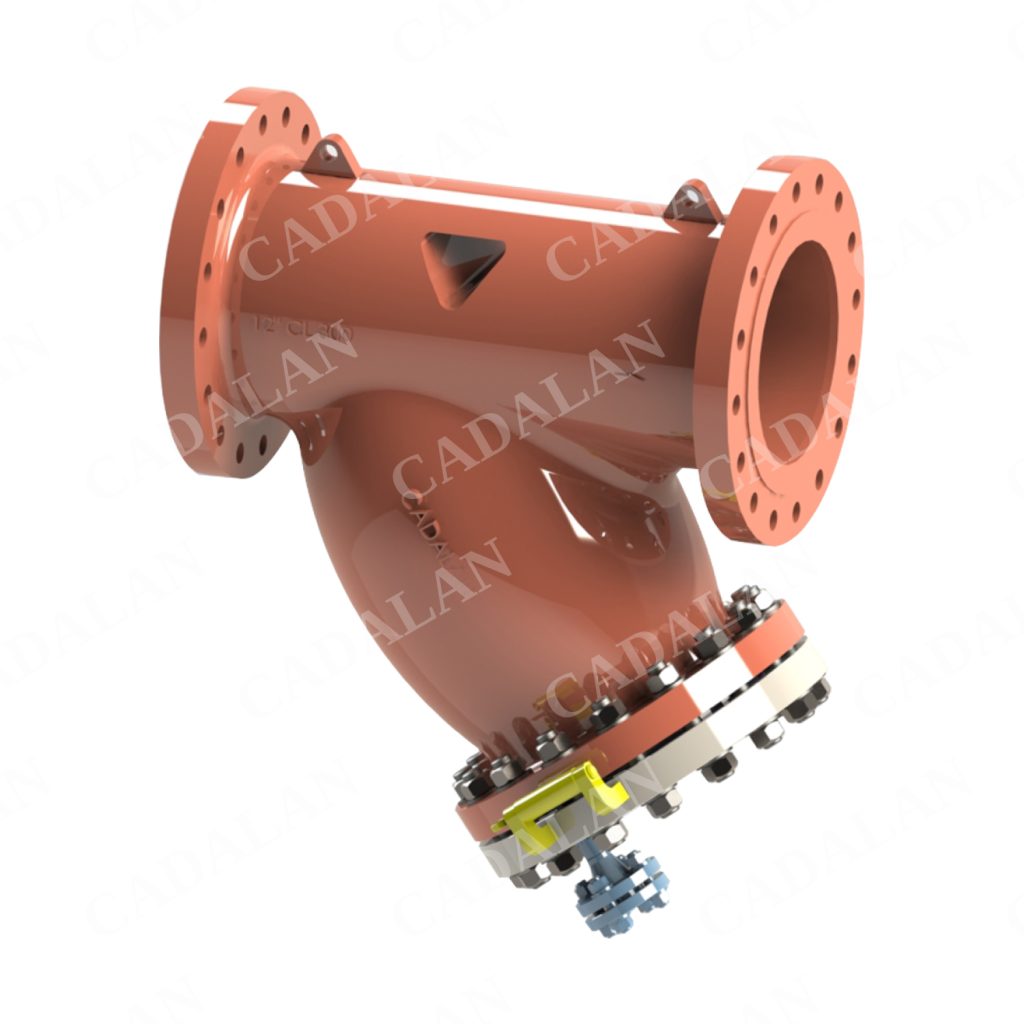

Y Strainer

Y Type Strainers a large quantity of debris can be removed from the pipelines, we offer quick delivery of Fabricated Y Type Strainers and free flow in Casting Strainer

- Size: 1″ – 24″ inches

- Types: Casting, Fabricated & Butt Welded

- Connection: Flanged & Butt Welded

- Installation: Horizontal tilting possible to a certain angle

- Class: #150, #300, #400, #600, #900, #1500, #2500 up to #10,000 depending upon the customer requirements

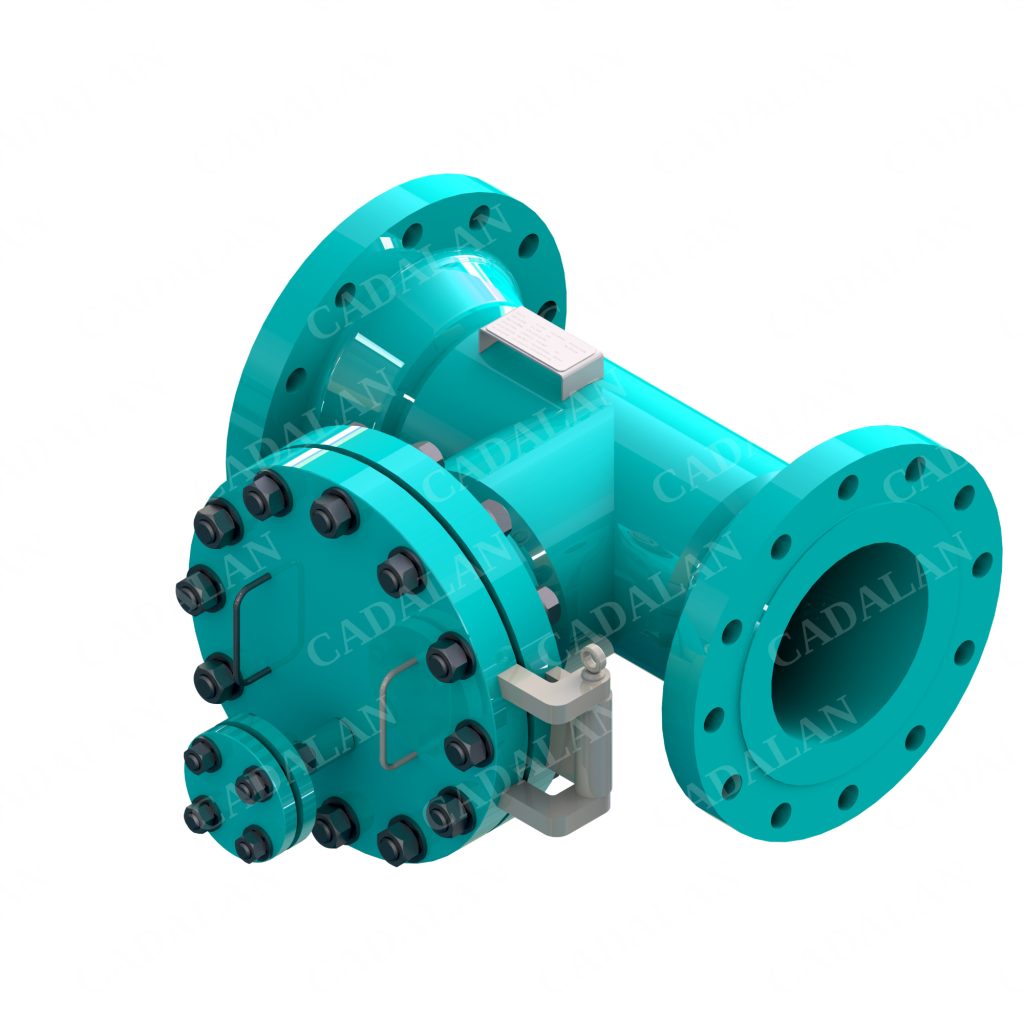

Duplex Basket Strainer

We supply Duplex Basket Strainers with highest quality and standards. Duplex Basket Strainers are designed for applications where continuous flow must be maintained while cleaning filter baskets.

The strainer uses integral 3 way stainless steel ball valves with PTFE seals. This design provides drop tight shutoff eliminating costly and potentially dangerous leakage into the chamber not in use which can occur in some other duplex strainer designs. This also eliminates some problems which can occur in particular suction conditions where in other designs air ingress could occur. All parts of the valve mechanism are accessible after removing the basket chamber without taking the strainer out of the pipeline.

- Size: Upto 24 inches

- Class: #150 up to #2500

Basket Strainer

We offer Basket Type Strainers in different configurations Basket Type strainers can remove a large amount of dirt when compared to the Conventional Strainers. In Process Industries where a large amount of suspended solids are to be removed, Basket Type Strainers are the ideal strainer considered

We supply two types of Basket Type Strainers:

- Duplex Basket Strainers ( Three way Valve)

- Simplex Basket Strainers

- Size: 1″ – 48″ inches

- Types: Casting, Fabricated & Butt Welded

- Connection: Flanged & Butt Welded

- Class: #150, # 300 , # 400 , # 600, # 900, # 1500, # 2500 up to #10,000 depending upon the customer requirements

Conical Strainer

Conical Strainers are known as Temporary Strainers, and these Conical Filter Strainers are used for the filtration of the system.

We are suppliers of Cone Type Temporary Strainers in fully various designs. The Conical Temporary Strainers are mostly used for testing purposes by new plants.

Conical Strainers are very cost-effective straining solutions in many applications. Where the amount of material to be removed from the flow is relatively small, resulting in long intervals between screen cleanings, the strainer screen is manually cleaned by shutting down the line and removing the strainer cap.

Conical Strainers are of three types:

Cone Type

Bucket Type

Boat Type Filter

- Size: 2’ – 48 inches

- Connection Type : Flanged ( RF , FF , RTJ )

- Filter : SS316 , SS3I6L ( Dual Grade )

- Class: #150, # 300 , # 400 , # 600, # 900, # 1500, # 2500 up to # 10,000 depending upon the customer requirements

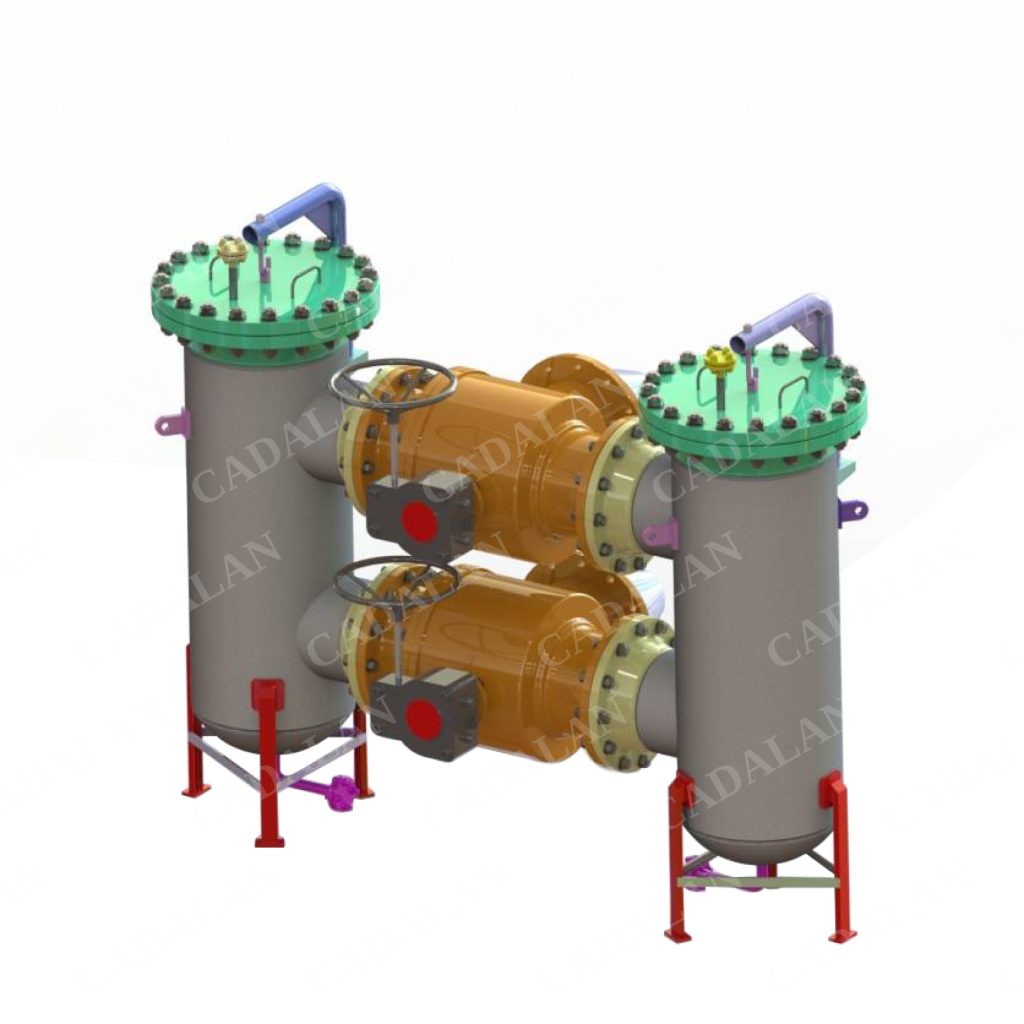

Self Cleaning Basket Strainer

Self-Cleaning Strainers are a motorised strainer that is used to continually remove contaminants and debris from an industrial pipe system. The flow of liquid enters the strainer at the bottom and works its way upwards through the strainer and then out. Any unwanted debris is caught inside the strainer and pushed to the bottom. When the differential pressure reaches a set point the flush valve at the bottom opens and removes the contaminants.

- Size: Depending upon the customer requirements

- Types: Fabricated and Casting

- Connection: Flanged & Butt Welded

High Pressure Basket Strainer

High Pressure Y Strainer

High Pressure Strainers

Construction Material

- Class Rating : 3000, 5000, 10000 Api Standards

- Material : AISI 4130, ASTM A694 GR F65

- Clamp : API 16 C Standard

- Size : As Per Customer Requirements

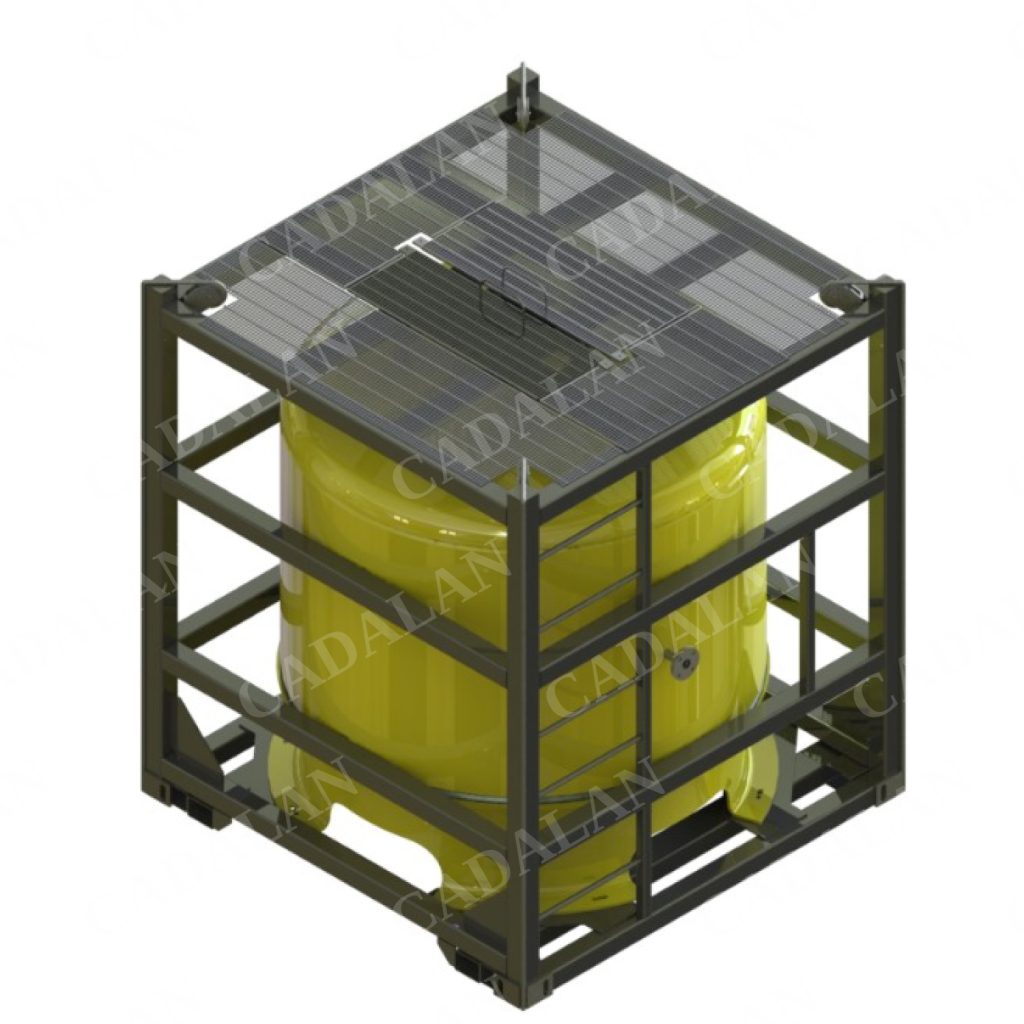

Surge Tank

Dust Collector

Dust Cyclone

Pressure Vessels

A pressure vessel is a closed leak-tight container (normally cylindrical or spherical) designed to hold fluids (i.e, gases or liquids) at a pressure substantially different (higher or lower) from the ambient pressure. They are usually made from Carbon Steel or Stainless Steel and assembled from plates by welding method. However, other materials like Aluminium, Copper, Non-Metals, etc also find usage as pressure vessel material in some specific situations. Even though most pressure vessels are basically long cylinders with two heads at both ends, they can take the shape of a sphere or cone.

Piping Speciality Fittings

Gasket & O Rings

Mud Dump Valve

High Pod Condensate Tank

Eductor

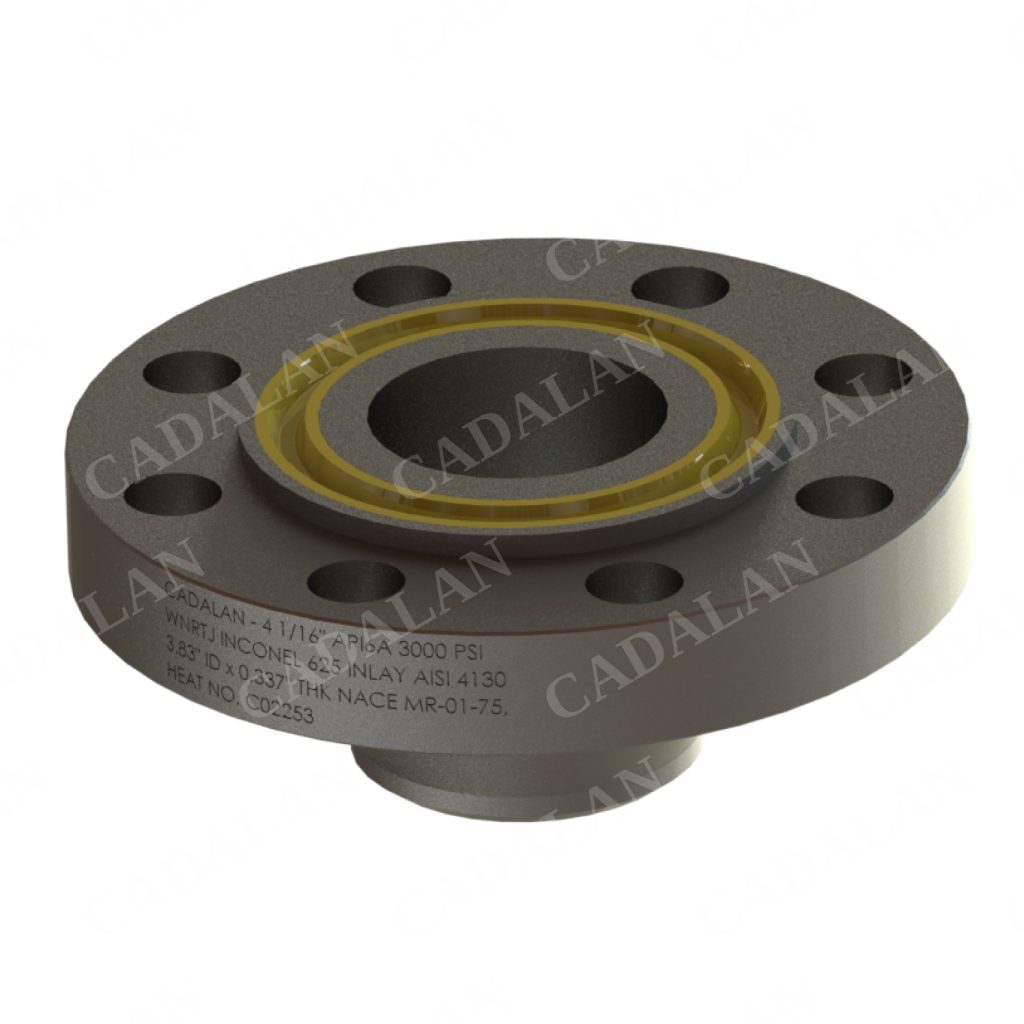

Weld Overlay Flanges

ARIZATECH offers a unique manufacturing which:

Allows for customizing configurations for process requirements

Specially sized bodies to meet flow efficiency and maintenance spares needs

With specialized cover options that offer cost saving improvements over heavier castings.

Partnership with

CONTACT US

ArizaTech GmbH

Harburgerstrasse 210 E

21614 Buxtehude, Germany

Office: +49 4161 5582 244

Mobile: +49 151 1225 0537

E-Mail: info@arizatech.com

Web: www.arizatech.com

CR Nr. / HRB: 208204

Amtsgericht Tostedt, Niedersachsen